Our vision

Mobility and environmental protection can go hand in hand. We can achieve both goals with the help of carbon-neutral fuels.

The key lies in closing the carbon cycle: If recycled CO2 is used in the production of synthetic fuels, the burning of the fuels in airplanes and ships is carbon-neutral.

Sustainable

Affordable

Scalable

Carbon-neutral mobility

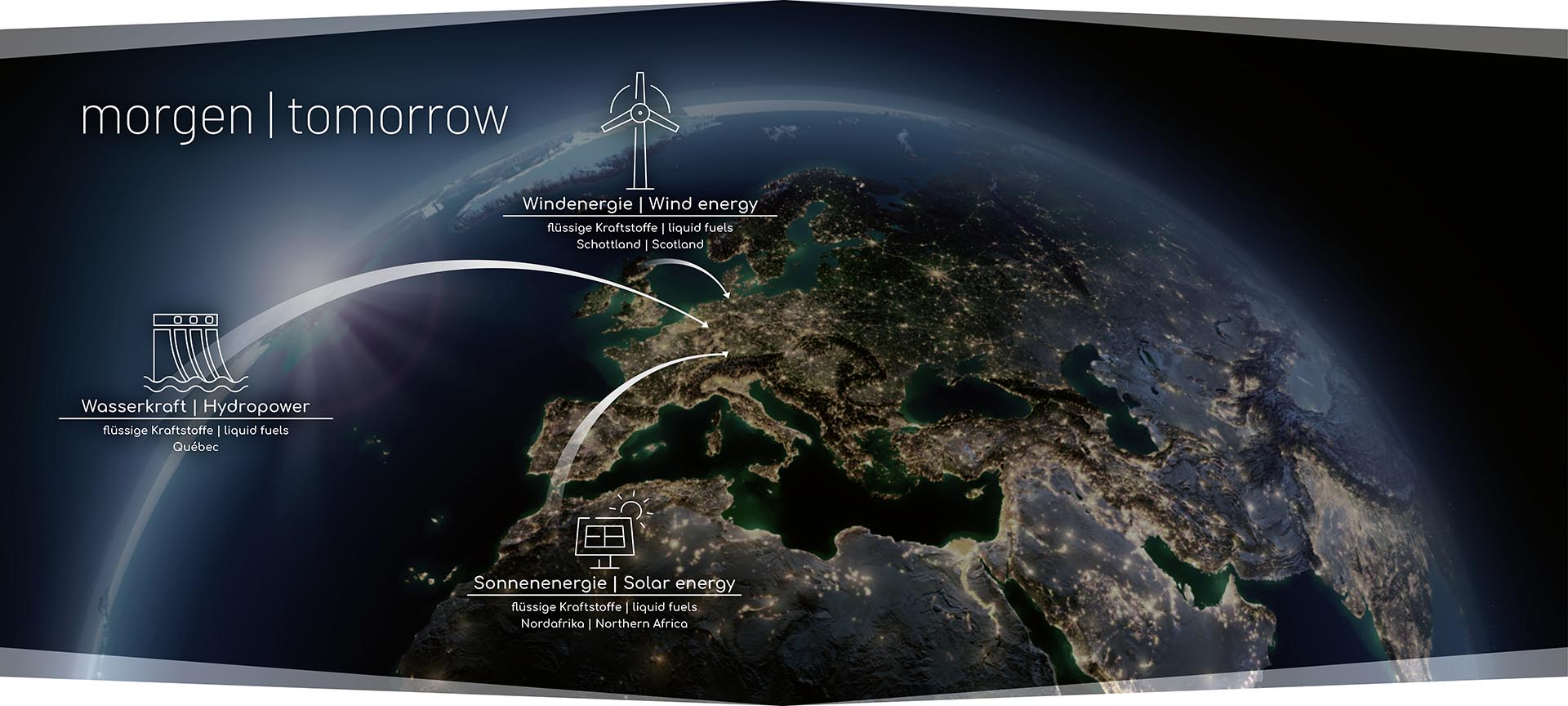

Each year, around 3900 billion litres of fossil fuels are consumed for the purposes of global mobility. This results in CO2 emissions of over 9100 million tonnes per annum. In a world geared towards sustainability, fossil fuels are being replaced – by synthetic fuels, hydrogen and renewable energy.

Synthetic fuels are ideal for both air and sea transport. This is because they can be used to cover long distances thanks to their extremely high energy density. They also play an important role in agriculture, road transport and construction.

Our credos

Our technology

Maximum use of the input materials

The different process stages are realised in a unique and patented 3-in-1 zone reactor. The reactor works without catalysts and achieves a selectivity of 100% due to the intelligent process design. And, since no by-products are produced, no materials and no energy are lost.

Maximum efficiency

The production of the synthesis gas has an energy efficiency of 86%. If the synthesis gas is reused in Fischer-Tropsch fuel synthesis, the resulting efficiency of 72% sets a new industry benchmark.*

* By comparison, the classic power-to-liquid process achieves an efficiency of 40%.

Maximum CO2-reduction

When combined with wind power, CAPHENIA’s Power-and-Biogas-to-Liquid (PBtL) process enables a CO2 reduction of 92% – a new industry benchmark.

- 100%

Selectivity

- 86%

Efficiency

- 92%

CO2-reduction

%

Selectivity

%

CO2-reduction

%

Efficiency