Our technology

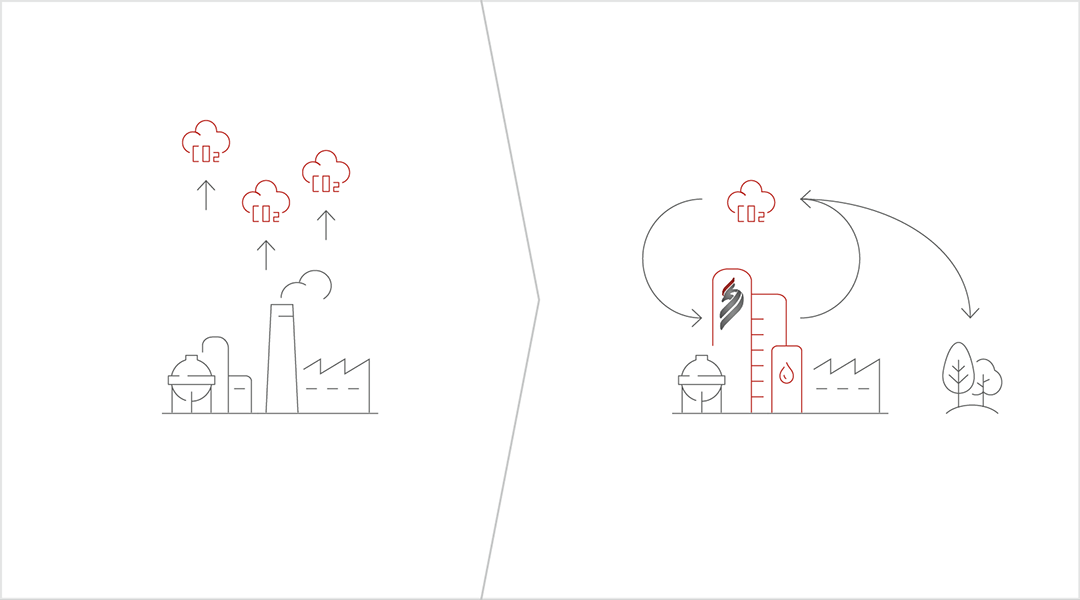

The CAPHENIA process is a technological innovation based on the novel combination of three known sub-processes, and the only one of its kind across the globe.

CAPHENIA produces a synthesis gas from biogas, CO2, water and electricity. Synthesis gas is an intermediate product, which can then be used to produce synthetic fuels or other chemical products.

CAPHENIA’s USPs lie in the 3-in-1 zone reactor – it allows chemical reactions to be controlled in a targeted manner.

Conventional processes require many reactors and units to produce synthesis gas. Production in the CAPHENIA zone reactor is simpler, faster and more cost-effective. CAPHENIA technology is highly efficient and requires significantly less electricity than conventional processes. Due to the reactor design, which has been created with upscaling in mind, CAPHENIA can produce synthetic fuels quickly in large quantities.

PBR-500

PBR-5K

PBR-50K

CAPHENIA 3-in-1 zone reactor

The model series

PBR-500

- Active power plasma torch: 250 kW

- Syngas production: 1280 tpa

- Potential fuel production: 500 tpa • 1,875 l/day

- CO2 consumption: 607 tpa

- Methane consumption: 332 tpa

- Electricity consumption: 3.9 MWh/t

- Diameter (Ø): 2 m

PBR-5K

- Active power plasma torch: 2500 kW

- Syngas production: 12,800 tpa

- Potential fuel production: 5000 tpa • 18,750 l/day

- CO2 consumption: 6,070 tpa

- Methane consumption: 3,320 tpa

- Electricity consumption: 3.9 MWh/t

- Diameter (Ø): 2 m

PBR-50K

- Active power of plasma torch: 25 MW

- Syngas production: 128,000 tpa

- Potential fuel production: 50,000 tpa • 187,500 l/day

- CO2 consumption: 60,700 tpa

- Methane consumption: 33,200 tpa

- Electricity consumption: 3.9 MWh/t

- Diameter (Ø): 6.3 m

The process steps in the 3-in-1 zone reactor

1. Plasma zone

The key technology of the CAPHENIA process is the high temperature plasma process. At a temperature of about 2000°C, methane (CH4) is broken down into a carbon aerosol (C) and hydrogen (H2).

2. Boudouard zone

In the Boudouard zone, the carbon aerosol (C) is combined with carbon dioxide (CO2) and converted into carbon monoxide (CO). This conversion is based on the well-known Boudouard reaction, which takes place at temperatures of around 1000°C. In this reaction process, the high thermal energy of the gas from the plasma zone is fully utilised and converted into chemical bonding energy.

The CO2 can come from biogas, CO2 air separation (Direct-Air-Capture/DAC) or CO2 flue gas separation (Carbon-Capture-and-Usage/CCU).

3. hetWGS zone

In the heterogeneous water gas shift zone (hetWGS), the remaining carbon aerosols (C) react with added water vapour (H2O) to form carbon monoxide (CO) and hydrogen (H2). The composition of the synthesis gas (CO + H2) can be flexibly controlled.

The CAPHENIA process achieves an industry-leading efficiency due to the successive process reactions in the 3-in-1 zone reactor.

4. Synthesis gas converter

The synthesis gas is the starting material for a large number of products. In fuel production, synthetic fuels are produced in a synthesis gas converter.

Synthetic fuels are not only climate-friendly, but also have a significantly higher degree of purity than fossil fuels. When they are burned, significantly less sulfur dioxide and fine dust are produced.

The CAPHENIA process

USPs

The CAPHENIA process has a selectivity of 100%. There are no by-products and therefore no energetic losses.

When it comes to producing syngas, the CAPHENIA process achieves a record efficiency of 86%. This is made possible by the intelligent design of the 3-in-1 zone reactor and the 100% selectivity.

Synthetic fuels from the CAPHENIA process have a CO2 reduction of up to 92% compared to fossil fuels. This brings the CAPHENIA process closer to CO2 neutrality than any other fuel production route.

- 100%

Selectivity

- 86%

Efficiency

- 92%