ZDF films report about CAPHENIA in Bernau am Chiemsee

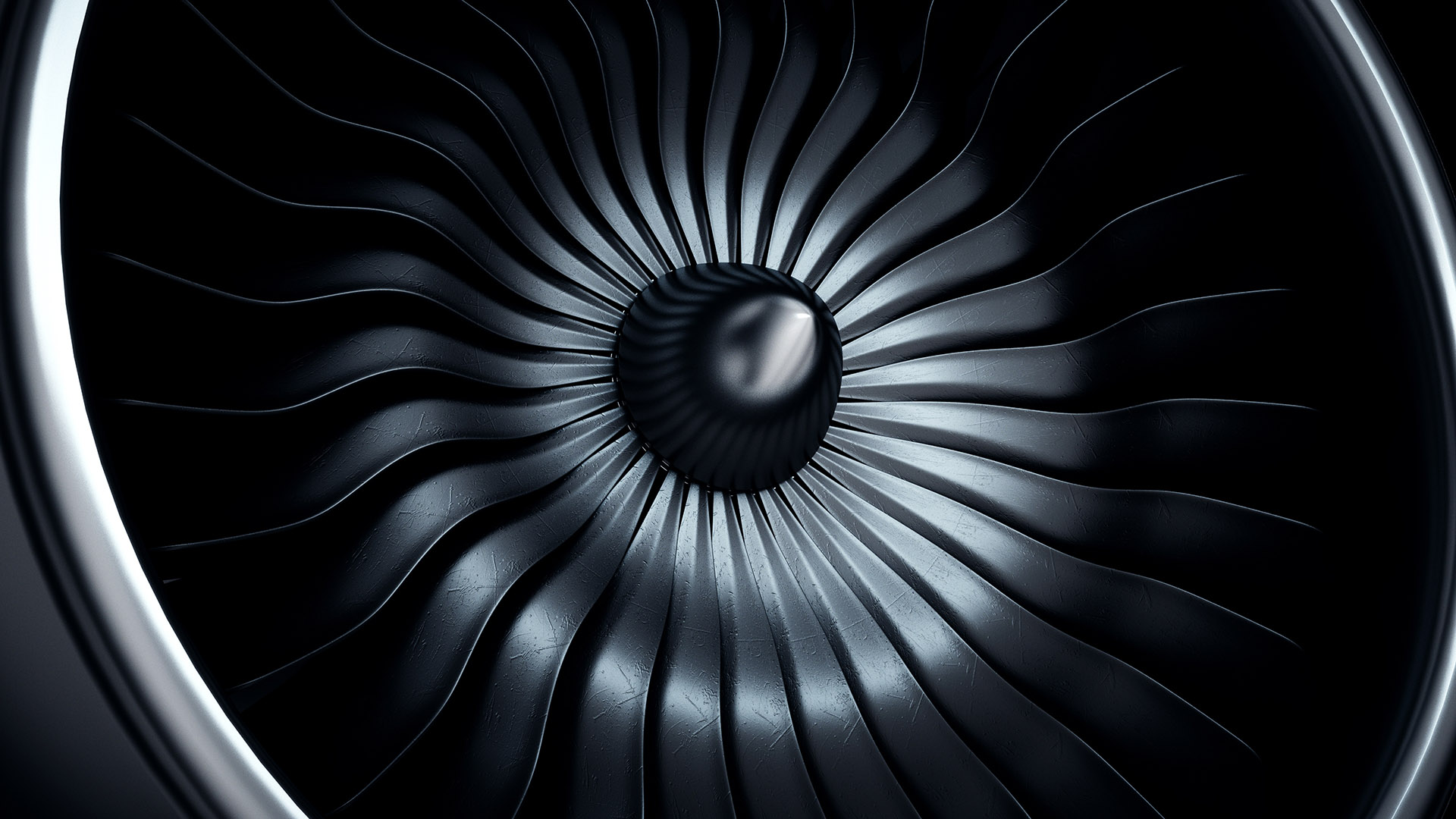

In Bernau am Chiemsee, CAPHENIA is a start-up that has developed a technology that will revolutionize aviation worldwide. Mark Misselhorn and his team at CAPHENIA produce synthetic fuel that produces no climate-damaging CO2. But previous processes for producing green kerosene require large amounts of renewable energy.

Mark Misselhorn: “We have found a different way of doing this because we see the difficulty that renewable energy and the expansion rates will be very limiting over the next decades. So you should find additional energy sources ideally, for example with biogas.”

Methane is produced from biological waste, such as green waste or industrial sewage sludge. The methane is heated and split into carbon and water. Water and CO2 are added. This produces carbon monoxide and hydrogen – so-called synthesis gas. This can be used to produce synthetic fuels such as kerosene, diesel and gasoline. This is a promising process, as Germany has set itself the goal of adding at least 2% synthetic kerosene to aviation gasoline by 2030.

Mark Misselhorn: “In Germany, we actually have the option of covering more than half of the total kerosene demand with waste materials alone. You can’t just produce aviation fuels – it’s always a mixture: Diesel and gasoline also come out in the end. These fuels can be used immediately in all mobility sectors.”